Garage floors endure heavy abuse from vehicles, tools, and chemicals, making protection essential. Concrete sealers form the first line of defense, penetrating the surface to repel oil stains and moisture. Epoxy coatings create a durable, seamless barrier that resists chips and cracks while simplifying cleanup. Interlocking plastic tiles offer removable protection with drainage channels for wet areas. For budget-conscious homeowners, high-quality garage mats absorb impacts and contain spills. Each option balances cost, durability, and installation effort to match different garage uses and budgets.

Epoxy floor systems provide the most comprehensive garage protection. Two-part epoxy kits bond permanently to concrete, creating a glossy, chemical-resistant surface. Flake additives improve traction while hiding dirt between cleanings. Professional-grade systems withstand hot tire pickup better than DIY versions. Proper surface preparation—including acid etching or grinding—ensures long-lasting adhesion. Though initially more expensive than other options, epoxy’s 10+ year lifespan makes it cost-effective for active garages. The non-porous surface also prevents oil and grease from soaking into concrete.

Interlocking garage floor tiles offer versatile protection without permanent installation. High-density polyethylene (HDPE) tiles resist automotive fluids and extreme temperatures. Modular designs allow replacing damaged sections easily without redoing the entire floor. Some tiles feature anti-fatigue properties for comfortable standing during projects. Ribbed surfaces provide traction while allowing debris to fall through for easy sweeping. These tiles work well over uneven concrete or as temporary solutions for renters. Their snap-together installation makes them popular DIY projects completed in a weekend.

Concrete stains and dyes provide decorative protection with subtle texture. Unlike coatings that sit atop concrete, stains penetrate deeply while allowing the natural surface to breathe. Acid-based stains create unique marble-like effects, while water-based dyes offer vibrant color options. Both options require sealing afterward to lock in color and provide stain resistance. This approach suits garages doubling as workshops or hobby spaces where aesthetics matter. The slightly textured finish improves traction but may require more frequent resealing than thicker coatings.

Maintenance extends any garage floor protection’s effectiveness. Epoxy floors need occasional degreasing and touch-ups in high-wear areas. Tile systems benefit from periodic removal for thorough subfloor cleaning. Sealed concrete requires resealing every 2-3 years depending on use. Immediate spill cleanup prevents permanent staining regardless of protection type. Placing absorbent mats under leak-prone vehicles adds an extra defense layer. Quality floor protection transforms garages from utilitarian spaces into clean, organized areas that better serve their multipurpose roles in modern homes. The right choice depends on your vehicles, activities, and desired maintenance level.

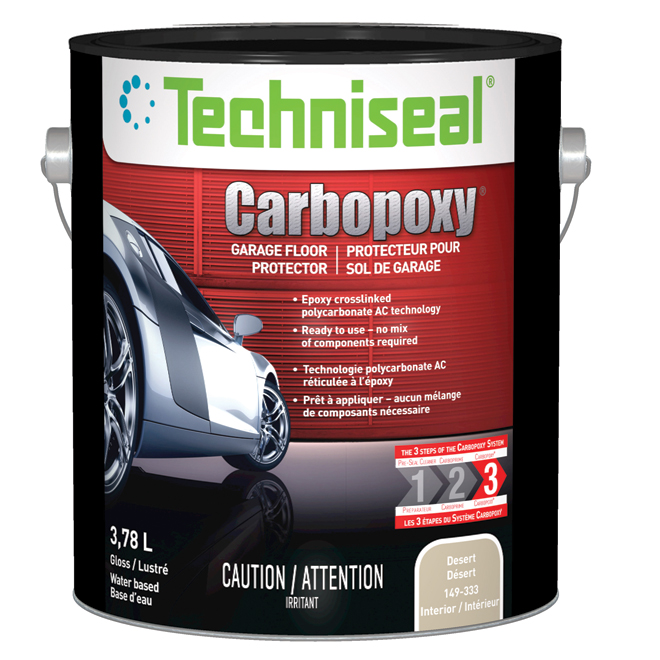

TECHNISEAL – Garage floor protector Réno-Dépôt

TECHNISEAL Garage floor protector 149-333 RONA

Are Garage Floor Tiles Any Good? – Garage Transformed

Garage Floor Coatings – Galaxy Concrete Coatings

Protecting your Garage Floor – Spectrum Overhead Door LLC

Part 1 – Installing aluminum diamond plate wall panels in garage, how to cut around an outlet

How to Prepare Surface for Garage & Factory Floor Protector – YouTube

8 Best Garage Floor Covering of 2022 [Expert Reviews & Buyers’ Guide] – New Garage Source

Decorative Floor Coatings – Diamond Kote Decorative Concrete Resurfacing and Epoxy Floors

Weather Stop Garage Door Floor Seal Fitting Instructions – YouTube

Related Posts: