Structural concrete floor panels offer a robust solution for modern construction, combining durability with rapid installation. These prefabricated panels are engineered to provide superior load-bearing capacity, making them ideal for commercial, industrial, and multi-story residential projects. Manufactured under controlled conditions, they ensure consistent quality and dimensional accuracy. The panels integrate reinforcement such as rebar or post-tensioning cables to enhance structural integrity. Their use reduces on-site labor and construction time, as they arrive ready to install. This efficiency makes them a cost-effective choice for large-scale developments.

Design flexibility allows structural concrete panels to meet diverse architectural needs. They can be cast in various thicknesses and spans to accommodate different load requirements. Custom finishes, including exposed aggregate or polished surfaces, eliminate the need for additional flooring materials. Hollow-core designs reduce weight while maintaining strength, simplifying transportation and handling. Some panels incorporate insulation layers to improve thermal performance. These adaptable features enable architects to create open, column-free spaces with fewer structural limitations. The panels’ versatility supports both functional and aesthetic project goals.

Installation advantages set these panels apart from traditional poured concrete. Crane-lifted into position, they form immediate working platforms for subsequent construction phases. Precise manufacturing minimizes the need for on-site adjustments or leveling compounds. The dry construction process reduces weather-related delays compared to wet concrete pours. Properly installed panels require only grouting at joints to create a seamless floor surface. This speed of erection significantly shortens project timelines while maintaining high quality standards. Contractors value the predictability and reduced waste these systems provide.

Performance characteristics ensure long-term reliability. The panels exhibit excellent fire resistance, often achieving 2-4 hour ratings without additional protection. Their mass helps regulate indoor temperatures, contributing to energy-efficient building envelopes. Sound transmission between floors is significantly reduced compared to lightweight alternatives. The non-combustible nature of concrete enhances building safety, particularly in high-risk occupancies. These performance benefits make structural panels suitable for schools, hospitals, and other critical infrastructure where resilience matters most.

Maintenance considerations favor concrete panels over other systems. The monolithic surface resists wear from heavy equipment and foot traffic. Unlike steel decks, they require no corrosion protection treatments. Minor cracks can be addressed with epoxy injections rather than full replacements. The inert material supports various floor coverings or can function as the finished surface with appropriate treatments. Lifecycle costs prove economical due to minimal upkeep requirements over decades of service. These low-maintenance qualities make structural concrete floor panels a prudent investment for forward-thinking builders and developers.

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

STRUCTO-CRETE® Brand Structural Panels USG

Hollowcore Precast Concrete – Precast Plank u2014 Mid-States

Prefabricated floor panels composed of fiber reinforced concrete

STRUCTO-CRETE® Brand Structural Panels USG

Hollow-core slab – Wikipedia

Aerial Floor System Product u2013 Aerial Precast Concrete

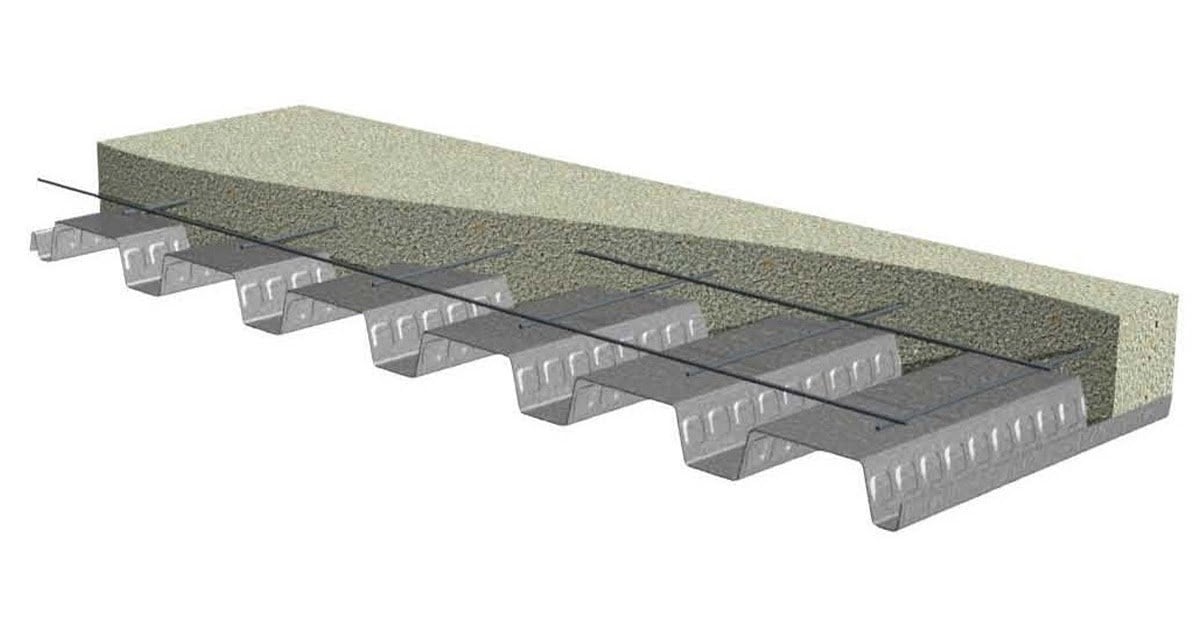

Metal Deck For Concrete: Types u0026 Uses of Composite And Form Decking

Related Posts: