The efficiency of the epoxy flooring of yours is going to be immediately affected by the way in which you prepare the surface area. Epoxy flooring is certainly becoming more popular every single day. One is the fact that an epoxy flooring will repel any, chemicals, dust, dirt, and water other form of stain that carpet will soak in. Epoxy flooring for companies has a lot of pros.

Epoxy Paint Over Tile Floor

Should you choose an epoxy floor coating for you warehouse, you will not be forced to be concerned about floor scuffing, scraping or perhaps skidmarks showing up. In general, these anti-slip agents are actually chips that are available in colors which are several and are actually sprinkled on top of poured epoxy (prior to it curing). Hardwood floors or even carpet floors usually get stained as well as the style of the room is marred.

Secret Ways on How To Paint Tile Floors Like A Pro Painting tile floors, Floor design, Tile floor

Epoxy flooring is often done by a contractor if it is a commercial job, but you'll find numerous different sets out there that homeowners can buy to epoxy their garages and basements. With this quality hence you have an alternative of having a sturdy flooring resistant to water, stains and chemicals and also one which infuses a sample of elegance.

Epoxy Over Tile – Watersofthedancingsky.org

Epoxy Floor Systems – Concrete coatings – Epoxy Floors – Epoxy flooring – https://www.e

KFC – Overnight Over Tile Floor Coating Silikal – YouTube

How to Apply Epoxy Coating Over a Tile Floor DoItYourself.com

Epoxy Flooring-Over Tile-Finish – YouTube

epoxy floors – Google Search Floor paint design, Epoxy floor, Floor tile design

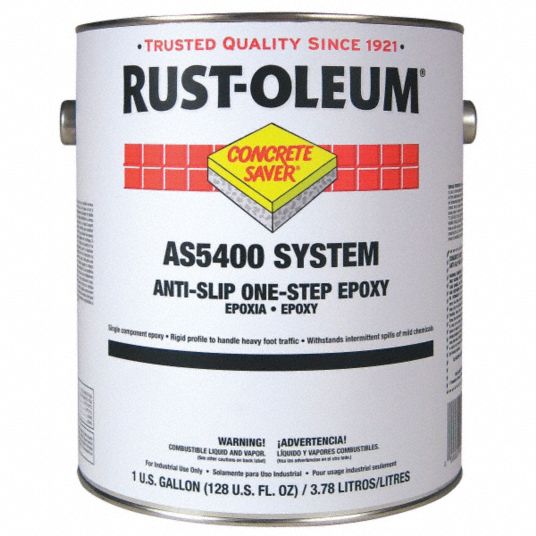

RUST-OLEUM Flat Epoxy Ester Anti-Slip Floor Coating, Tile Red, 1 gal. – 1F718AS5468402 – Grainger

Floor Coating Over Tile – Carpet Vidalondon

How to Paint and Stencil Tile with Chalk Paint Barnaclebutt

Epoxy Floor Coating vs. Tiles: When to Choose an Epoxy Flooring – YouTube

Image result for concrete floor ideas basement Metallic epoxy floor, Epoxy floor paint, Epoxy

Easy Garage Floor Coating and a Giveaway! – Shanty 2 Chic

‘Paint-Your-Own Granite’ Is A Thing, And Apparently It Actually Works HuffPost

Related Posts: